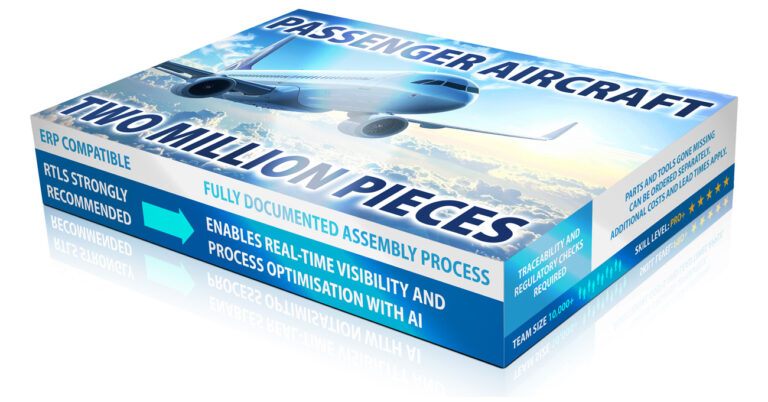

Taming Complexity in a

High-Stakes Industry

Modern aviation manufacturing and Maintenance, Repair, and Overhaul (MRO) operate on a scale of almost unimaginable complexity. An aircraft like the A350, for instance, is assembled from approximately 2 million individual parts, each requiring meticulous documentation, certification, and coordination. This environment demands absolute precision, yet even the most detailed plans collide with the unpredictable reality of the shop floor, threatening both process integrity and schedule reliability.

Despite sophisticated Enterprise Resource Planning (ERP) systems, persistent “blind spots” create a fundamental gap between the planned process and the actual situation. This data-reality gap is driven largely by the unpredictable “human factor”—the natural tendency for people to deviate, adapt, or make mistakes. The result is wasted time, costly delays, and a constant state of reactive problem-solving.

The strategic imperative for aviation leaders is clear: they must close the gap between plan and reality. Real-Time Location Systems (RTLS) provide the foundational data layer to manage this complexity, transforming operations from reactive firefighting to proactive, data-driven optimization. To understand the power of this solution, one must first appreciate the depth of the challenges it is designed to solve.

The Anatomy of Inefficiency: Unseen Friction in Aviation Operations

In the high-stakes environment of aviation, the strategic importance of understanding operational friction lies in its cumulative cost. Seemingly small, everyday issues can escalate into significant delays, compliance risks, and financial losses. These inefficiencies are often invisible to traditional management systems, yet their impact is felt across the entire value chain, culminating in expensive outcomes like “traveled work”—work that must be completed out of sequence at a different facility due to preventable delays.

The High Cost of the Search Effort

One of the most pervasive sources of non-added-value work is the time workers spend searching for misplaced tools, materials, and parts. This search effort is a direct, physical manifestation of the data-reality gap. On vast shop floors, workers can walk up to 10 kilometers per day in search of necessary items, a staggering figure that translates directly into wasted time, extended production cycles, and increased labor costs. This represents a persistent and expensive pain point across nearly every segment of the industry.

The Data-Reality Gap

A critical disconnect exists between the status reported in ERP systems and the actual situation on the shop floor. For instance, a forklift driver might scan a barcode for a delivery station while still in transit to satisfy a KPI, marking a task as complete in the system before the physical work is done. This practice of “cheating” the system masks underlying problems and forces shift managers and leadership to make decisions based on flawed data. When the digital record and physical reality diverge, process integrity breaks down, leading to flawed planning and constant disruptions.

The Human Factor: The Unplannable Variable

At the root of this operational unpredictability lies the “human factor.” People, by their nature, deviate from instructions, adapt processes on the fly, and make mistakes. This constant, dynamic interaction creates what is known as an “NP-hard problem”—a level of complexity that cannot be fully solved by top-down planning or mathematical algorithms alone. While traditional systems like ERPs strive for a perfectly planned state, they cannot account for the irreducible variance introduced by human action. Perfect planning may be mathematically impossible, but managing the resulting variance is not.

Overcoming these deep-seated, human-driven challenges requires a new layer of intelligence that bridges the physical and digital worlds.

The Quuppa Solution: From Raw Data to Actionable Insight

Addressing the deep-seated challenges of operational friction requires a strategic philosophy anchored by a simple truth: “You can’t fix what you can’t see.” Quuppa’s Real-Time Location System is designed to deliver this essential visibility. By providing an accurate, live, and comprehensive view of physical operations, Quuppa makes the invisible frictions of the shop floor visible and, therefore, manageable, closing the data-reality gap with a foundational data layer that translates raw location information into actionable business intelligence.

Quuppa’s RTLS delivers three core, interconnected values to the aviation industry:

- Real-Time Visibility: This is the foundational “dot on the map” capability, providing an accurate, live view of all tagged assets—from certified tools and critical parts to material trolleys. This eliminates the search effort, giving workers and managers immediate knowledge of where everything is.

- Historical Process Intelligence: The value of RTLS extends far beyond live tracking. By recording these “dots” over time, we unlock Historical Process Intelligence. Recorded location data enables the creation of heat maps that reveal bottlenecks and spaghetti diagrams that show actual material and tooling flows. This turns a live view into a data-backed blueprint for optimization.

- Automation and Integration: This verified data can then be integrated with enterprise systems (ERP, WMS, MES), enabling event-driven Automation that aligns digital workflows with physical reality. For example, a tagged material trolley entering a geofenced area can automatically trigger a booking in the ERP system or a request for material replenishment, reducing manual input errors and improving data accuracy.

The true value of this technology is best understood through its practical application in real-world scenarios.

Case Studies in Transformation: RTLS in Action Across the Aviation Sector

Examining real-world deployments provides concrete proof of how RTLS moves beyond theory to deliver measurable operational and financial improvements for industry leaders. These cases demonstrate how a foundational layer of visibility can solve distinct, high-stakes problems across manufacturing and MRO by closing each organization’s unique version of the data-reality gap.

Airbus: A Strategic Approach to Solving Core Logistical Pain Points

Airbus began researching real-time location solutions in 2017 to address a critical need: identifying materials and bridging the visibility gap within its vast logistics stream. Officially adopted in 2019, the Quuppa system was implemented to tackle extensive search efforts and the misplacement of parts. A key technical advantage was Quuppa’s use of a proprietary channel, which allowed it to operate effectively in industrial environments where standard Bluetooth was often restricted. By providing an accurate, real-time view of assets, Airbus could ensure the right parts were in the right place at the right time, advancing its “factory of the future” vision.

Safran Aircraft Engines: Eliminating Expensive Delays in MRO

In a massive deployment, Safran Aircraft Engines implemented RTLS to track over 30,000 tools across two facilities totaling over 75,000 square meters. The primary objective was to eliminate the expensive operational delays caused by missing tools—a common but costly problem in MRO environments. The system provides instant location information for every critical tool, drastically reducing search time. Beyond preventing delays, the system also enables proactive monitoring of all tools, allowing Safran to schedule preventive maintenance and ensure every asset remains in optimal condition.

Fokker Services Group: Driving Automation and Paperless Operations

Fokker Services Group adopted RTLS with several strategic goals in mind: to automate material flow in its MRO operations, achieve a fully paperless shop floor, and improve a critical industry metric—OEM On-Time-Deliveries. The system’s ability to provide real-time visibility into assets and processes via dynamic dashboards enables faster problem detection and proactive adjustments. This creates a direct link between the operational reality on the shop floor and key performance metrics, allowing areas for improvement to be identified and addressed immediately.

While these individual successes are compelling, the true strategic power of RTLS emerges when these operational gains are aggregated and translated into quantifiable business impact across the enterprise.

The Tangible ROI: Quantifying the Value of Visibility

While individual case studies are powerful, the true strategic value of RTLS is realized when its benefits are aggregated and analyzed across key business functions. This technology translates directly into measurable improvements in operational efficiency, process automation, decision-making, and compliance, delivering a clear and compelling return on investment by closing the gap between data and reality.

Translating Visibility into Value

Benefit Category | Specific Improvement | Business Impact |

|---|---|---|

| Operational Efficiency | Drastically reduced search time for tools and materials. | Increased worker productivity, reduced production cycle time, and minimized non-added-value labor costs. |

| Process Automation | Automated ERP bookings for process steps, defective batches, and material replenishment. | Reduced manual input errors, improved data accuracy, and freed up human resources for higher-value tasks. |

| Enhanced Decision-Making | Provided managers with a real-time, accurate view of shop-floor status, closing the data-reality gap. | Enabled faster and more effective responses to disruptions, improving adherence to production schedules and enhancing overall operational control. |

| Compliance & Traceability | Ensured meticulous, real-time tracking of every certified tool and component throughout the MRO and manufacturing process. | Strengthened audit readiness, ensured adherence to strict airworthiness regulations, and future-proofs the operation against evolving regulatory landscapes. |

These quantifiable benefits make a clear business case for RTLS not merely as a tactical tool, but as a strategic investment for the future of aviation operations.

The Future of Aviation is Visible

The aviation industry’s immense complexity, coupled with the inherent unpredictability of the “human factor,” can only be mastered with an accurate, real-time view of physical operations. Quuppa is the bridge between the physical world and digital systems, providing the foundational real-time data layer that makes this essential visibility possible. As our brand promise states: “Quuppa helps our customers see what they’ve been missing.”

In an era of accelerating digital transformation, where technologies like AI promise to revolutionize industry, real-time visibility is no longer just an operational advantage. It is a strategic prerequisite. High-quality location data is the fuel for intelligent automation, predictive analytics, and process excellence. It is the foundation upon which future innovations will be built.

For the aviation leaders of tomorrow, real-time visibility is not merely an operational tool—it is the foundational prerequisite for competitive dominance.

Let’s talk.

Flying your process blindfolded and relying on gut feeling eventually makes your gut hurt.

Replacing guesswork with real-time visibility brings confidence and predictability, and helps you navigate through turbulence (and sleep better).

Let’s get together and put the pieces together.

This form is the fastest way to reach the right expert. Please provide a few details to help us route your message and prepare a meaningful reply.

Prefer a direct contact? Visit our Key Contacts page.